New Year brings in optimism for roll forming manufacturers

Customer excitement leads Samco Machinery to invest in growth

By Jim Austin, Targeted Content Inc., for Samco Machinery

TORONTO, January 17, 2017 – Orders were up, spending was up and optimism remains up. Customers looking to invest in roll forming solutions are heading into 2017 expecting to roll up their sleeves, work hard and have a great year, according to Bob Repovs, CEO at Samco Machinery in Toronto.

During the recently completed calendar year, Samco Machinery was as busy with capital investments as it was manufacturing solutions for its customers. The company increased its own workforce by more than one-third and improved its employee benefits package to help recruit and retain the best people.

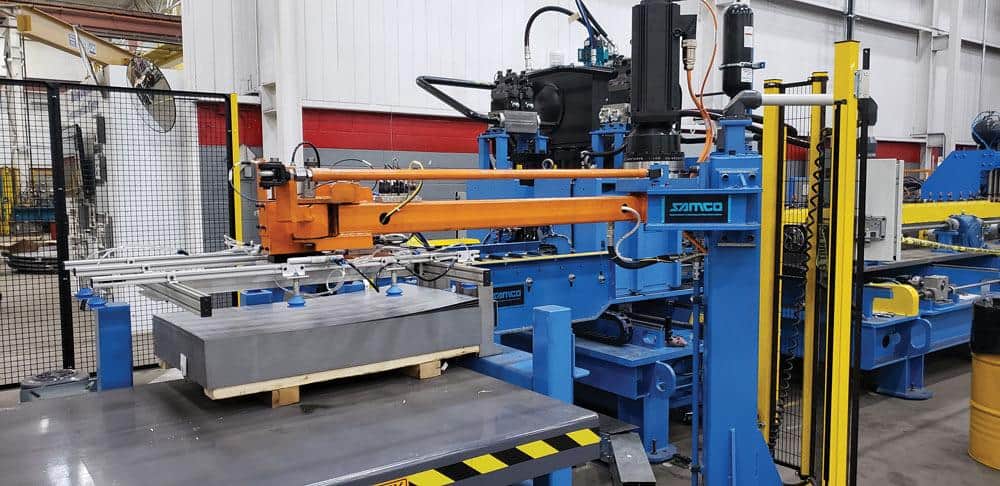

“We added a vertical machining center, CNC lathe, surface grinder, milling machine, key seater and a paint booth,” Repovs says. “Our facility underwent significant building, hardware and software upgrades, throughout the year. These investments were made to improve efficiencies and help ensure we meet our commitments.

“Our customers are busy, they’re excited about 2017,” Repovs says, recalling conversations at trade shows in the fourth quarter of 2016. “We are thankful for our customers who supported us well in 2016 which has enabled us to have a solid order book heading into the New Year. With growth, we’ve had to deal with some new challenges, but that’s the fun part. We’ve refined our project management processes to ensure we’re still getting things done on time and with the quality our customers demand.”

Much of the optimism is a direct result of the U.S. presidential election. Incoming President Donald Trump promises a large infrastructure investment plan and aims to undo key regulations that many in the construction industry believe inhibit project development and job growth.

Samco Machinery’s strength lies in its diversity, producing roll forming equipment for a multitude of industries: building and construction, automotive, racking and shelving, garage door, HVAC, and solar. Diversity helps produce better equipment solutions because challenges dealt with in one segment can help another segment.

“Customers are looking at building new plants,” Repovs says. “A couple of years ago, priorities were different, but customers are building again. For example, with an increase in building, the demand increases for racking and shelving equipment. After some slowdowns in the automotive industry, customers are again purchasing equipment.

“As we know, labor is not cheap in North America, so people are investing in automation equipment and technology,” Repovs says. “They’re buying engineered products and solutions and doing everything they can to optimize their processes.”

Samco’s new Paint Booth and CNC machine

|

|