About Metal Roofing Machines

Samco Machinery’s high-efficiency shake roof tile rollformer produces tiles and shingles to the desired length.Parts are pre-stamped and embossed and then sheared to the desired length before being fed into the rollforming line to form the sides for the locking function.

Our Metal Roofing Solutions Key Features:

- Fully programmable servo feeder for different lengths and includes entrance basket rolls and strip guides

- Hydraulic press (est. 600 tons) to stamp the embossing and step features, and cut to length

- Length control system with encoder and measuring wheel

- Pick and Place System that picks and places pre-cut materials on the powered Launching Conveyor

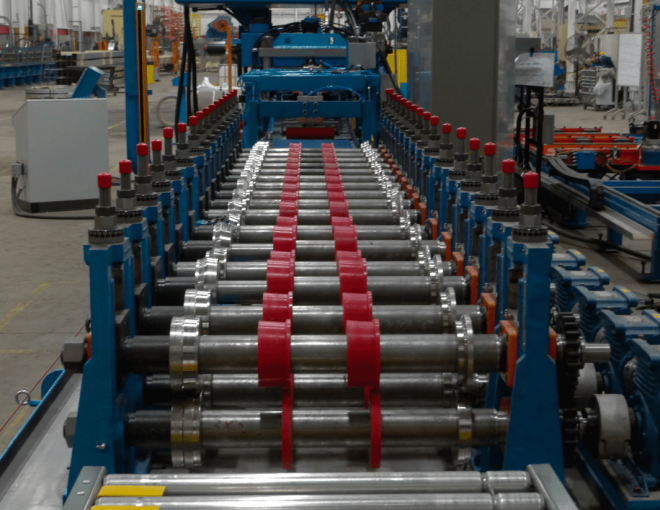

- SAMCO Universal rollformer with factory laser aligned stands & shafts

Metal Roofing Equipment Optional Features

- Embossing unit for different (Cedar and Slate) roof tile patterns and includes roll sets

- Automated transfer die system to automatically clamp/unclamp dies in the punch press