The Devil’s in the Details

Avoid Disappointment With Your Next Rollforming Purchase

By Bob Repovs

Many Engineers, Plant Managers and line workers look forward to the day a large capital expenditure is approved by their management team. This is the piece of roll forming equipment that will make them more productive than ever, beat all production records, and prove that many months or even years of cost justification will pay off.

All this excitement and adrenaline can be shot down in a hurry if the machine shows up and is partially installed and those “little surprises” appear. Your boss then asks when the machine will be fully operational and offer the return on investment you promised. You don’t have a solid answer for him because there are small yet indescribable issues. What most people don’t know is these small surprises or issues can be avoided. The new style of equipment purchase today involves far more than a purchasing agent receiving approval, processing the paperwork and sending the purchase order to the capital equipment supplier of choice. Today’s customer must be involved with the supplier before the order is placed and during the development of the equipment.

THE QUOTATION STAGE

One of the most critical elements people overlook is the development of the quotation.

Rollforming equipment manufacturers have spent thousands of dollars and hours developing the next best thing that will reduce set-up and increase run times, as well as offer complete turn-key systems. The difficulty many purchasing agents have is they don’t have the opportunity to involve active members of the team during the buying decision. That is, where the value is to be spent and what the end-user really needs. Some possible options or upgrades people often overlook are:

Auto Gauging Systems—Ever consider the cost of gapping the mill?

- Quick Die Change Systems—Change-over and physical movement of large dies is a common oversight.

- Slug Removal Systems—Powered conveyor options are an option.

- Lubrication System—Traditional flood or roller applicator system—no coolant tank or nozzles are required, and there is no mess.

- Front-end System—Upgrades to minimize coil change-over time—ever consider double-ended uncoilers, hold-down arms, peeler tables, threading tables and end shear welders?

- Overhead Cable Trays—These can be used for carrying electrical wires overhead instead of on the floor where there are safety hazards and forklift obstacles.

- Powered Width Adjustment or Rafting—This is another set-up time reduction.

- Guarding—Do you prefer light curtains or fence guarding?

- Precut or a Post Cut-off System—Ever count up your cut-off inserts?

- On-site Installation and Training—Don’t underestimate the installation help and training your people will need. You will expect a fast payback, so provide help and training from the start.

The sales representative handling your account should be offering and educating your team about these options and upgrades during the quotation process. Many people are not aware of what the market has to offer, especially if they have not purchased equipment in the last three to five years. Once all options and upgrades have been selected and the quoted line speeds have satisfied your requirements, a supplier of choice will receive the purchase order.

This is where most companies and people believe they are out of the picture. Once an agreement has been made with the supplier, they assume they are no longer involved in the process and the machine will arrive just as ordered. However, this is where the critical details and issues can be resolved and discussed—at the development stage.

The Development Stage

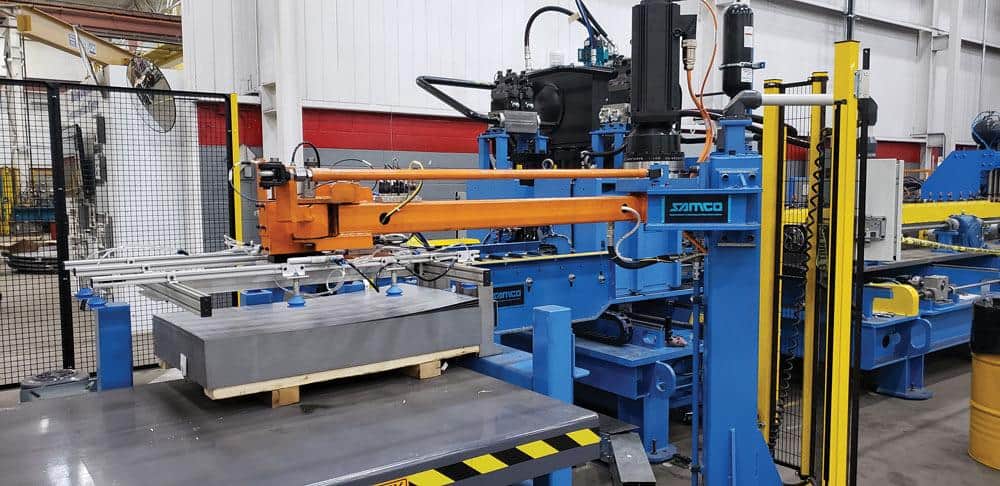

Proactive companies that purchase and have flawless rollforming line installations don’t just make miracles happen or get lucky. They simply become a member of the design team and work with the engineering department to iron out specific details on their line. After all, you are the customer and you have paid out a significant portion of your budget on this rollforming line. Wouldn’t it be nice if the line arrived and you knew exactly how it would look and where components would be placed and there would be no interferences in the building? And it would be great to know the process flow of your raw material would be stored, manufactured and shipped in a process that makes sense.

Customers can make a large impact on the design of their own equipment if they provide critical information from the start. Preferably, customers should visit their supplier and meet the design team during the developmentof theirline.Asmallup-frontinvestmentinairfarewillsave much more time, money and aggravation for when your rollforming line appears at your facility.

Here are some critical elements that must be considered when managing and developing your project:

- Building Layout—Are there interfering pillars, footprint and/or ceiling height restrictions?

- Line Direction—Will it be right-left, left-right, or U-or L-shaped layouts?

- Scrap Removal Systems—Forklift access or underground conveyor systems should be considered.

- Quick Die Change—Large dies may need a crane or forklift access.

- Power Requirements—This can be different by country, state or even city.

- Working Pass-line Heights—Is there “other” equipment interfacing with the newly purchased rollforming line?

- Equipment Color—Ever think about adding this for the builder? Is there a standard color you prefer?

- Hydraulic Power-pack Location—Determine if it should be on the floor or overhead.

- Electrical Panel and Operator Locations—Far too many customers don’t think about where the operator will work or where the main power drops currently are in the building. This can cost you thousands of dollars if not communicated in the plan from the start.

- Guarding—If you need a fence, where will you access the machine for maintenance?

- Part Orientation—Is the part legs up or legs down? This is critical if feeding a packaging line or part transfer system.

What You Want

When evaluating a rollforming supplier, consider if they have a culture that welcomes two-way partnership and development of your rollforming line. Do they practice effective project management, and are they looking out for your best interests? As I said earlier, this is your line and your money. Get what you paid for and what you want!

Most of these details and issues may seem to be common sense and everyday practice. They are, but as you’ve heard “the devil’s in the details.” Next time you and your team have that major cost justification approved, remember to include the appropriate members of the team and don’t fall short in your own involvement and input to the design of your next rollforming line.

Bob Repovs is president of Samco Machinery Ltd., Toronto.