Samco assists gutter supplier to make a critical decision with their growing business

Custom Roll form equipment manufacturer leverages vertical integration to not only construct tooling but to roll parts in-house for a customer not ready to invest in a complete turnkey machine.

TORONTO, June 8, 2016 – Start-up costs have been known to inhibit the actual start-up of even the most solid business ventures. Samco Machinery has discovered a way to help new businesses in need of a custom roll formed product to reduce their start-up costs while producing top-quality products.

Universal Manufacturing & Design of Palm Harbor, Fla., was in search of roll forming assistance for the chassis component of its unique and innovative Gutter Guard product. Purchasing full turnkey machinery to form this unique product would have cost more than $400,000. Troy Merkley, VP of Operations at Universal, said it didn’t take long for his company to realize that finding some manufacturing help was going to go a long way towards getting the new business off the ground.

“We did a lot of research, talked to a lot of companies that do roll forming,” Merkley says. “I would say that 60 to 70 percent of those we talked to said, no, they couldn’t do it. I don’t know if it was because the bends were too difficult or if it was because they were too busy, but they said no.”

After most roll forming operations eliminated themselves from the competition, Samco Machinery was one of three remaining when Universal Manufacturing & Design was ready to make a decision. The final decision was made at Metalcon 2015 in Tampa, a short drive from Palm Harbor.

“Honestly, we felt a synergy with the people at Samco,” Merkley says. “We got to meet them face to face at Metalcon, have dinner with them. That was important to us, to work with people we feel comfortable with. Samco was open to discussions and suggestions all through the process.”

Darryl Levesque, Vice President of the Rolling Division at Samco Machinery, works with existing and potential customers interested in purchasing custom roll form niche market parts as well as advising and understanding their strategic long term goals and objectives.

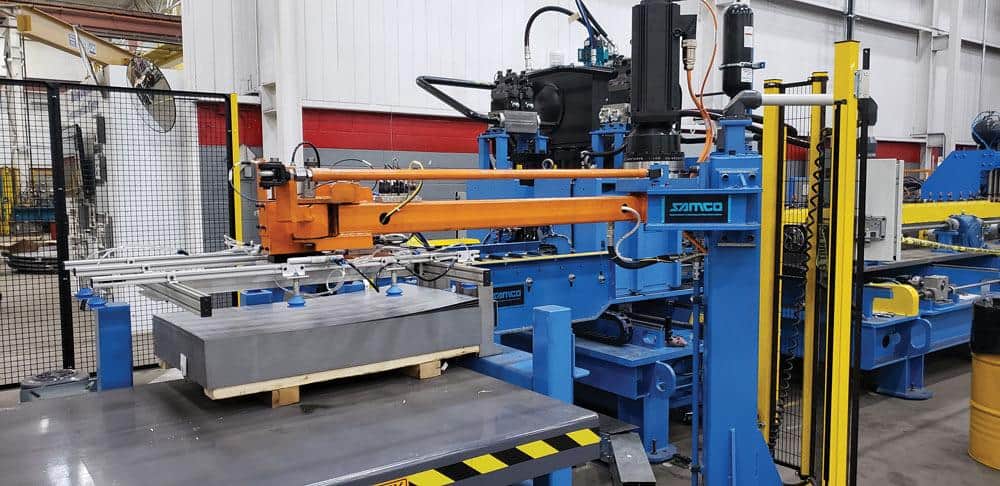

Levesque takes customers through a process to help them make the best decision for their operation. Investing in a full turnkey roll form solution is a major financial investment decision for any business, and all areas of their organization must be fully engaged from the plant footprint, to raw material handling and finished inventory storage, Levesque states. Universal Manufacturing & Design came to Samco Machinery with a design and drawing for the chassis component of their gutter protection product. After upfront engineering due diligence and collaboration relative to the innovative profile of the product, Samco engineers started their FEA (Finite Element Analysis) analysis. Samco’s state of the art COPRA FEA allows them to test their roll form tooling on a virtual tooling tryout mill before any material is cut, it pinpoints potential forming problems, and predicts actual strip shape at each roll-stand saving the customer time and money, according to Levesque.

“This is how we resolve any upfront issues before we build the tooling,” Levesque says. “You want to avoid cutting tooling more than once, or making multiple adjustments to the tooling during initial tryout. This was one of the more challenging parts we’ve had the pleasure of working on as it required over 220 roll tools constructed to make the product.”

The tooling fits into a standard Samco 24-pass roll former and can be easily changed over to produce the chassis component for 5-inch or 6-inch gutters. For Universal Manufacturing & Design, contracting Samco Machinery to do the roll forming was the best way to get started. Samco was shipping the finished chassis parts to Palm Harbor, Florida in mid-January for final assembly. The money saved by contracting Samco as opposed to purchasing a machine was used to take the product to market. For the first quarter of 2016, most of the product was sold “south of the Mason-Dixon,” Merkley says. “Now that it’s spring, our shipping is migrating north, Ohio, Virginia, North Carolina, Wisconsin, Minnesota, those are all good gutter states.”

UMD is on schedule to have 900,000 linear feet of the Universal Gutter Guard chassis produced in 2016, or about 225,000 4 foot length pieces. While Merkley hasn’t been to Samco Machinery in Toronto to see this unique part being roll formed, Levesque has shared videos and pictures throughout the tool development and into production. “It’s exciting,” Merkley says. “Having Samco as our contract roll forming partner was definitely the right direction for us to go. And right now, we have no plans to try and bring the manufacturing of this component in-house.”

Samco Machinery provides customers leading edge designs and cost-effective solutions to satisfy any metal roll forming project need. Maintaining ISO 9001 certification, Samco manufactures roll forming machines, decoilers, roll form dies and presses servicing a multitude of customers worldwide in varied industries.

Universal Manufacturing and Design produces and sells gutter protection products direct to contractors. Visit www.onegutterguard.com to learn more about Universal Manufacturing and Design and its unique line of gutter protection products.