Buying new vs. used equipment: What’s best for you?

Research a necessity to ensure the better decision for your operation

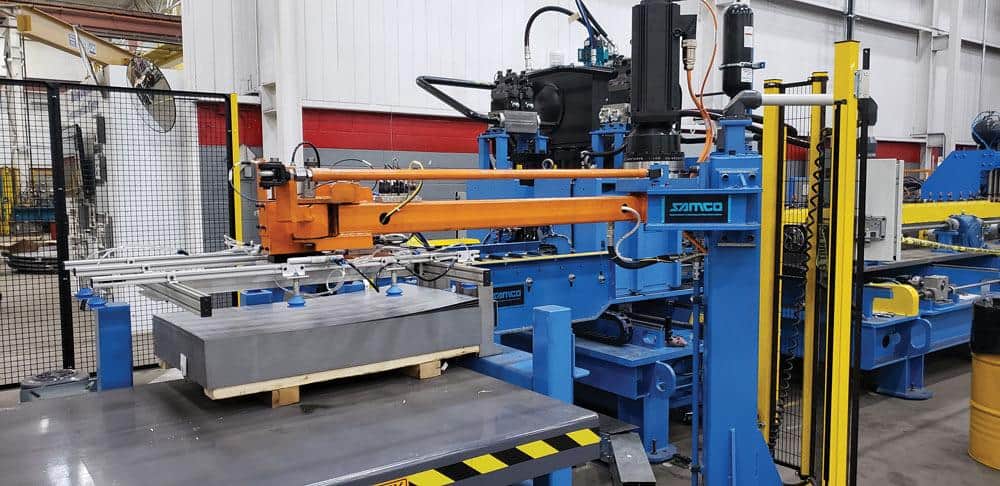

By Joe Repovs, Founder, Samco Machinery

TORONTO, November 2014 – Successful businesses are run by people who are prudent with how money is spent or re-invested into the business. The bigger the expenditure, the more research may be required to make the best decision.

The purchase of rollforming equipment is certainly a major investment in your business. Rollformers are often your operation’s most integral piece of equipment, so you want to make sure you’re purchasing a rollformer that will meet all your demands or can be updated to meet those requirements.

Is a new piece of equipment the best investment, or is there an opportunity to purchase a quality used rollformer at a significant savings? Being an OEM, obviously, I’m in favor of a customer buying new equipment – it eliminates a lot of worries and potential headaches. Purchasing a rollformer is more complex than purchasing a standalone production unit. Rollforming machines are one component in a system that has many moving parts; they require a great deal of synchronization to produce accurate components at relatively high speeds. The use of an OEM rollforming system manufacturer is highly recommended, if for no other reason than your own protection.

Having said that, there are obvious situations where the purchase of a good piece of used equipment makes sense. Purchasing used equipment is a viable market because the brand name machines are built to last. There exists a certain psychology out there, it’s the first inclination to look for a deal, for something used.

One good place to purchase used equipment is from someone who needs to downsize their business or perhaps to raise cash. A machine from a company in a different geographic market could make a great buy, price-wise, and you could purchase a machine that is ready to go, ready to start producing. One advantage with purchasing equipment in this fashion is the buyer can usually see the machine in action before writing a check. Plus, your production start is only dependent on how long it takes to transport and set up the equipment. Waiting for custom-made equipment from an OEM may take up to six months. You’re making money only when your machine is up and running.

A word of caution with purchasing used equipment from an individual … make sure there are no liens or encumbrances.

Another viable option for purchasing used equipment is at an auction. A general rule is that you should not pay more than 60 percent of the price of a new machine. That also applies when purchasing equipment from a dealer, which can be trickier. Buyer beware is the general rule when buying from a dealer because you’re buying “as is” and “where is.” You don’t get to see the machine in operation, so you can’t know what problems you may have to deal with.

Purchasing used equipment from an individual or a dealer also means you have no OEM warranty and OEM technical support and training. We’ve had customers who required a second round of training … you don’t know what you don’t know until you turn on the machine.

With the purchase of used equipment, you’re also missing out on the newest technology, a part of the life cycle of the machine as well as any depreciation allowance. Technology is changing all the time. The newest technology enables your machine to run a higher speeds, produce the most accurate products and allow for the greatest amount of flexibility with the geometry of products with the same tooling.

An often overlooked consideration when purchasing used equipment is the quality of your in-house maintenance staff. Maintaining these machines is vital to keeping them running. I’ve seen customers who have the staff to make it work and I’ve seen companies whose idea of maintenance is running the machine until it breaks. That’s zero-maintenance and it ends up being expensive.

The purchase price of used equipment is usually only part of the investment. Most likely, you still will require an OEM to rebuild the equipment, add tooling and, in most cases, new electronics. These can be challenging items to budget, requiring more research. OEMs are certainly capable of rebuilding basic machines and augmenting the entire system with new pieces of updated equipment, electronics and technologies.

We refurbish equipment, both ours and rollformers manufactured by others. Most of it ranges from 10 to 30 years old. People come to us with machines they want us to get running at 80 feet per minute. That’s an unknown with used equipment. It doesn’t matter who big the motor is, if the gears will only allow a machine to run 40 feet per minute, that’s all you’re going to get out of it.

Experts can even be fooled by the condition of used equipment until they see it running. Without seeing rollformers in operation, you don’t know the condition of the bearings and if all tooling is straight.

Finally, beware of any equipment that was stored outside. If someone comes to us with equipment that’s been stored outside and wants to know what’s worth, we tell them whatever they can get for scrap. If it sat outside for any amount of time, that’s what it’s worth. Damaging rust is not always visible to the naked eye, so it will require an in-depth inspection of the gear boxes. It’s probably not worth the potential problems.

At the end of the day, it’s a cost-benefit situation. If your volume of production justifies new, BUY NEW! The life cycle of a new machine is highly predictable when you’re in control of the maintenance.

If anticipated volume will be low, a used line may make more sense. However, please take into consideration if the brand is still in business. If not, spare parts can become a huge issue … not to mention the obvious lack of support.

If you are looking for pre-owned or refurbished equipment, Samco offers Samco brand machines as well as others, individual pieces or turnkey systems, retrofitting with other machines into new systems, full after sales support, commissioning and full training.