Focus on diversification, customer needs leads to success

Samco continues to adapt, innovate and meet new demands

By Jim Austin, Targeted Content Inc., for Samco Machinery.

TORONTO, February 4, 2015 – To succeed in today’s competitive world, those who conduct “business as usual” may be left behind.

Was your 2014 everything you hoped for your business? The economy would indicate that for most, 2014 will go down as a successful year, despite a slow start caused by an extended cold winter in parts of the United States and Canada. With growth in many sectors, manufacturers enjoyed a successful year and carry optimism into 2015.

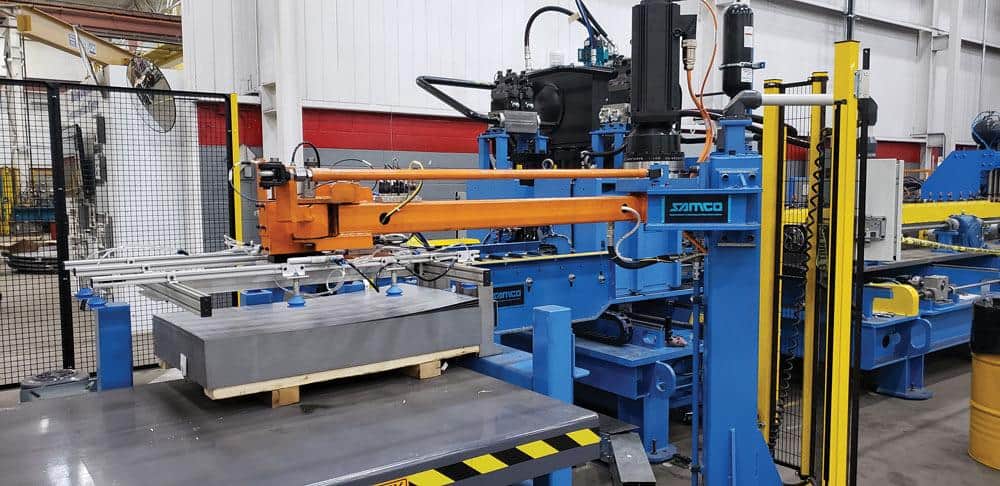

Samco Machinery, a manufacturer of rollforming equipment for multiple industries, completed the transition into its new plant as well as a new way of doing business. “We had a very good year,” says Bob Repovs, CEO at Samco Machinery in Toronto. “We’ve got our new facility up and going … it’s like moving into a new home, it takes a while to get all the pictures up where you want them. Now everything is laid out the way we want it and we’re running efficiently.”

Samco Machinery knows efficiency, having dedicated the last 43 years to helping customers run their own operations more efficiently. Repovs says customers producing in a variety of industries in both the U.S. and Canada were adding capacity and equipment in 2014. “Some are repeat customers, but some are new customers,” he says.

“Diversification is the key for us, producing machines for electrical, automotive, shelving and racking, garage doors, residential doors, steel siding, steel roofing, steel framing … and we can apply lessons we learn in one industry to others.”

Strength through Diversification

Diversification has made Samco Machinery a stronger company. When a company relies on its business from a single industry, it’s vulnerable when that industry experiences a downturn. Samco Machinery has increased production volume by finding new markets.

“As an engineering company, product diversification came natural as a result of our customer needs,” Repovs says. “Product quality, efficiency and throughput play a part in all industries, from loading raw material at the front end to handling finished product at high speeds. This “Voice of the Customer” approach has helped Samco grow across various industries in both product and geography.

“Given Samco Machinery’s technical bandwidth and reach into many industries, we are able to educate and consult our customers continuously. This can be done in ways of communicating market trends, changing material properties and helping understand technology advances as they transpire within our engineering teams.”

In addition to customers enjoying a successful 2014, Repovs says competitors also performed well during the last year. “They’re not slashing prices to get projects so that tells me they’re not struggling and that’s good for all of us,” he says. “2014 started out slow because cold weather lasted into March in some parts of North America. By the second quarter, things started picking up and that momentum is carrying over into 2015.”

Hear your Customer

The best way to ensure customers are getting what they want is to listen. Almost all Samco Machinery projects are custom machines requiring engineering solutions. To effectively listen to customers, it’s important to stay in touch. Repovs says Samco Machinery customers are updated on the progress of their equipment throughout the process, including updates from engineers complete with photos and charts. That’s the best way to ensure a successful project for all concerned.

“Our focused rollforming experts and in-house engineers explore our customer’s true needs, beyond their stated requirements,” Repovs says. “Our experience reveals unseen efficiencies, adds innovative technologies and brings a personalized approach to our customer’s floor, for both the experienced buyers and buyers that are new to the industry.”

Repovs says indicators are pointing to a successful 2015. “No one is slowing down or canceling projects,” he says. “We’re expecting 2015 to be better than 2014.”

For North American manufacturers, now is the time to be prepared to grow. That means more machinery purchases, especially in the U.S. and Canada. “Manufacturing is back,” Repovs says. “With a renewed emphasis on reshoring manufacturing jobs, 2015 should be another very good year. “Automotive is preparing for record years in 2016 and 2017. On the construction side, stud plants are being building in Florida. Both are good signs.”

(For more on bringing manufacturing jobs back to North America, visit the Reshoring Initiative website at www.reshorenow.org.)

Repovs believes it’s important to evolve and adapt with the needs of customers. “If we were doing it three years ago, we’re probably not doing it anymore,” he says. “You can’t keep doing business the way you’ve always done business. Technology has changed the way we do things, including marketing. You can’t just attend a couple trade shows and place a couple ads in a magazine. You have to get out there on websites, where everyone can find you.

Ultimately, Repovs believes diversification is a wise business strategy for any company, regardless of what they do. While some industries may be in a slow-down or possible recessionary spending cycle, others may be on the opposite side of the business cycle, growing and investing! “We have seen the extremes in 2008 when automotive and building construction crashed,” Repovs says. “But look at the energy industry, for example. Find your synergies and strengths and market yourself better.”

Samco Machinery provides customers leading-edge designs and cost-effective solutions to satisfy any metal rollforming project need. Maintaining ISO 9001 certification, Samco manufactures roll forming machines, decoilers, roll form dies and presses servicing a multitude of customers worldwide in varied industries. Visit www.samco-machinery.com or contact sales@samco-machinery.com for more information.