Samco Machinery evolves with the ever-changing roll forming industry

Customers keep raising expectations for roll former manufacturers

By Samco Machinery

The roll forming industry is a moving target… changing, evolving, advancing all the time. In today’s market, customers need agility; custom production at increased speeds within efficient footprints. This leads to a greater return on investment and lower production costs. And while this thinking is intuitively practical, it is far less easy. Samco Machinery has learned that if you want to make equipment perform to the increasing needs of customers, then the systems and people used to develop the equipment must also be as agile.

Samco Machinery innovates to meet the ever-changing demands of clients with the goal to exceed expectations. The custom roll forming market is very competitive. Samco’s services include consultation to ensure customers get the right equipment for the products they need to produce. Samco also installs all equipment, provides training, ongoing maintenance, support and spare parts.

Samco’s business is driven by roll forming demands in multiple business segments in countries all around the globe. The ability to communicate with customers globally has been a part of the industry’s evolution. The use of apps, video conferencing and the ability to share three-dimensional designs keeps the customer more involved and informed throughout the development of their machinery.

There are two kinds of customers. One kind of customer has a basic understanding of the equipment but focuses on the finished product and the performance needed to make a ROI. They trust your expertise to design the equipment to meet the performance and safety needs. The other kind of customer understands the product and performance but also wants to be involved in the design process, providing ideas, specifications and preferences. Typically they are looking for continuity, from prior machines or experience, making the transition as seamless as possible for the operators and maintenance staff. That means they need direct access to the development engineers and more involvement throughout the stages of engineering from design reviews to communication. Ultimately, both types of customers get exactly what they want in the end.

Project management has become as much a service for the customer as it has been for supporting internal activity to keep the project on schedule. Project management provides regular updates to keep the customer informed on their significant investment. Today’s customers don’t just order a machine and expect it to arrive on-time and to specification. They are actively engaged in the progress throughout development so there are no surprises.

Samco Machinery has perfected a system that focuses on a series of “milestones” that mark the progress of all of its projects. When someone says the project is at a particular milestone, everyone else knows exactly where in the process the project is, regardless of its complexity. That makes it easier and more efficient when it comes to answering customers’ questions.

Customer-Driven Innovation

Recently, Samco Machinery has introduced several innovations to the roll forming industry that were generated by the demands of customers.

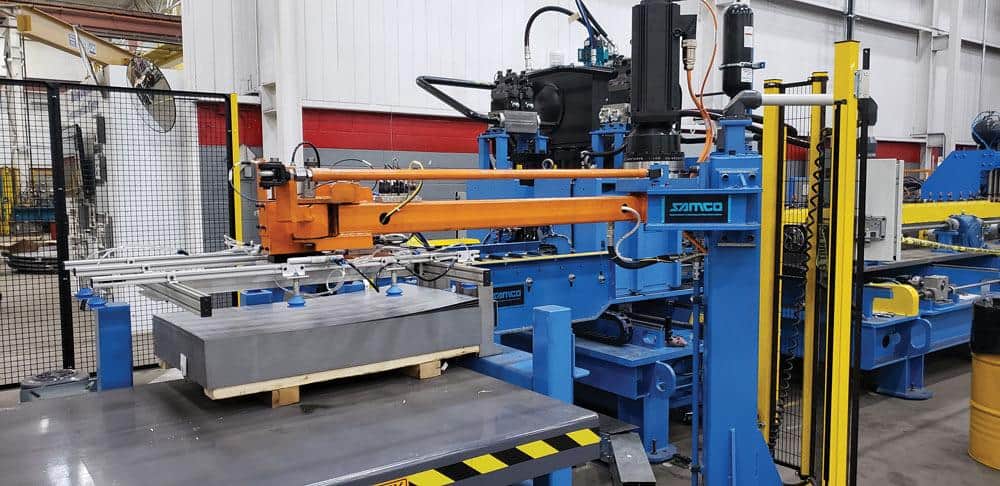

Material handling to replace people doing simple tasks because labor cost is high; The company recently developed a material handling system for an Australian customer with only two touch points, one where the raw material was loaded and the other where it was trucked away to be shipped. In between, the material was formed, stacked, shrink- wrapped, palletized, strapped and labelled. That level of automation requires sophisticated monitoring of data and reliable handling to prevent damage and mislabeling that may occur during production to ensure proper delivery. Click the following video links for examples: https://youtu.be/PhMrvIKqhac and https://youtu.be/K-Gnf1yPBcc

Customers are asking to enable new features all the time. It’s becoming common for office staff to download orders from office desktops directly to the roll forming machine so operators can concentrate on keeping the equipment running. That means more electronics, stable communication links, and more challenges in terms of order validation. Customers drive the need and the market responds.

Another recent innovation was the creation of a machine that accepted not only production data directly from a structural design program to the machine but included discreet print data distributed to 6 different print heads. The roll former produced a series of different parts in-line that included alignment and assembly marks, product information and kit building data. It was a very complicated innovation that involved specially created software and machine tracking sensors. An industry first.

Faster, stronger, sleeker

Customers used to accept the big robust machine as the norm. Bigger was better. Now they want value. It has to be built with less material, but be as strong as ever, with the ability to run faster. Customers recognize this sleeker model as a well-engineered machine, without the bulk that adds weight and cost.

Customers get a first-hand look of the Samco Machinery operation during a plant tour. The 164,000 square foot facility is configured with the flexibility to simulate the plant of any of its customers. Once they’ve been through the plant, there is a certain level of comfort that we can do what they ask.

Custom machines sold globally require quick responses to issues with any machine. Samco Machinery has the option to add remote access to the machines for its customers, meaning the customer doesn’t have to wait for someone to show up on a service call. The issue can be diagnosed remotely, getting the machine up and running … and making money … as soon as possible. It’s a comfort to customers knowing they don’t have to wait days or weeks to get things done. It also saves on the cost of travel for a technician.

Samco Machinery manufactures equipment for a variety of industries, including HVAC, garage doors, automotive, roofing and framing. The demands of each industry overlap with the others and the information they learn in one industry can be applied in others. That’s why the Samco staff includes 30 engineers. Every market segment has an opportunity to learn from the successes of others. That knowledge is best used for custom roll formers and Samco Machinery has parlayed that knowledge into a unique and successful business model.